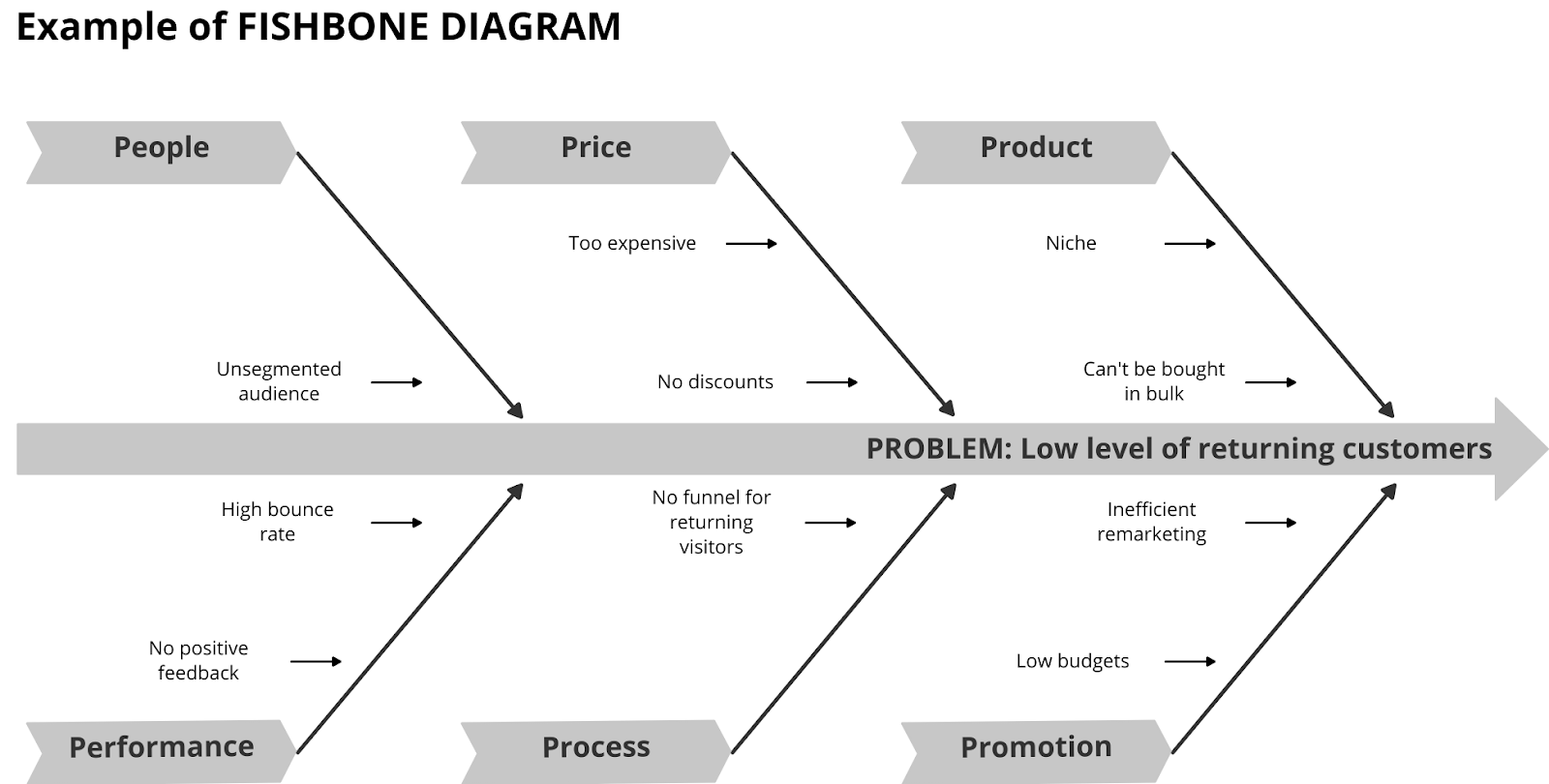

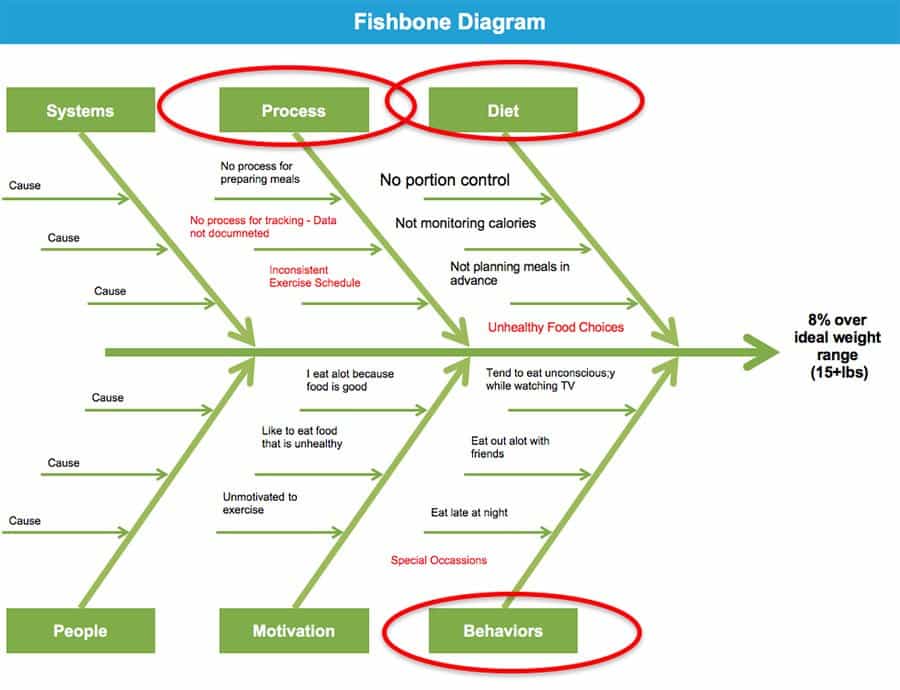

It is used when thinking about root cause analysis on a higher level, leading to solutions that have the potential to solve the problem once and for all. When drawn, the result looks like the skeleton of a fish hence the name. They are also good as a starting point for problem solving when you are completely unfamiliar with the manufacturing or business process. Cause and Effect Diagram: This tool identifies, manages and reveals the potential causes of a specific effect. A fishbone diagram is a graphical tool that is used to identify all potential causes of a process or product failure. You will know when a fishbone diagram is appropriate – usually when there are a lot of voices wanting to be heard around a particular problem. The Cause and Effect diagram is also referred to as the Ishikawa diagram or fishbone diagram. In other words, it is a visual representation used to find out the cause (s) of a specific problem. (2) It’s all about taking the right action after the meeting – be sure to use an action item tracker to document the who, what, and when of each action. A Cause and Effect Diagram (aka Ishikawa, Fishbone) is a pictorial diagram showing possible causes (process inputs) for a given effect (process outputs). Two additional tips: (1) Implement the quick wins – easy fixes that will make a difference, whether or not they directly impact the problem being discussed. (2) These sessions naturally fall into debates around potential causes, and your job as facilitator is to guide the group back on track, reminding them that we are here to gather and document potential causes. The reason for this: we often don’t know what the cause groupings will be until we’ve collected all of the potential cause. (1) It’s a good idea to use post-it notes first, rather than try to complete the fishbone diagram immediately. The next two slides cover tips for successful outcomes. But Pareto analysis and designed experiments are much more effective in finding top causes. Fishbone diagrams are great for organizing team input and generating ideas for possible causes. There are more arguments against fishbone diagrams than there are in favor of them. This slide shows an actual fishbone diagram example for shorted motor coils, using our Excel template. Overall construction – the problem statement goes at the “head of the fish,” and potential causes are grouped together to make up the “bones.” Introduction – general format and what the tool is used for. Here are some screenshots from the training file – The course is aligned to IASSC and ASQ exam, integrates lean and DMAIC methodologies using case.

Dmaic and ishikawa diagram free#

This free Fishbone Diagram training course provides you with the materials you need to share fishbone diagrams with other team members, customers, and suppliers. Fishbone diagram(Ishikawa) or cause and effect diagram.

0 kommentar(er)

0 kommentar(er)